Differential Choice

One of the biggest, most influential design decisions that can affect the driving performance of a car is the rear differential. The type of differential a team will choose practically decides how the car will handle and what kind of suspension and track width/length the car will need in order to perform well within competition.

In short, a rear differential in your everyday vehicle serves to make sure your tires don't slip every time the vehicle needs to turn, thereby extending tire life by reducing tire wear. This is because there is a different distance each wheel has to travel within a turn. In order to make sure each wheel travels a different distance in the same amount of time, there must be a speed differential between the wheels so that the wheels don't slip or suffer premature wear over time.

A secondary (and particularly important) purpose for choosing a rear differential is the ability to limit the amount of slip each tire has under acceleration and to bias torque to the rear wheel that has the greater traction.

Track conditions are usually considered to be inconsistent at best, meaning that most teams assume there will be some type of adulterant on the driving surface that impacts the tire's ability to mechanically adhere to the road. Classically, this type of contaminant would be water. However, these contaminants could also be simply loose gravel due to old asphalt, or even spilled oil due to an unlucky team's engine gasket failing. These act negatively on a tire's traction by adding unconventional lubrication between the tire and the pavement, lessening or even eliminating any traction the tire had. In an open differential, this completely stops the vehicle from moving until tire traction is regained.

In order to minimize this problem, most teams resort to using a limited slip differential (LSD), which does it's job by... limiting the slip. In broader terms, the LSD serves to limit the amount of traction lost between the tire and the pavement by biasing torque towards the other wheel, making sure that power isn't wasted, and making sure the other tire has enough power to accelerate the car, despite the traction loss that one of the rear tires has. The aforementioned track conditions are always considered in order to both be able to justify the use of a rear differential, and to finally aid in the decision process of a rear differential.

First, the most common type of rear differential that newer teams use the most is... none at all.

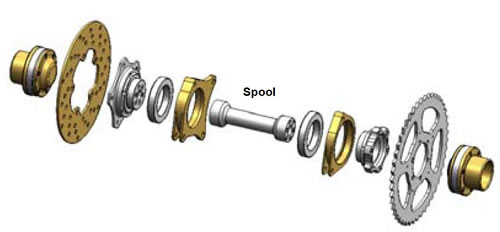

A spool type of differential, better known as a solid axle with the addition of a sprocket, is often used by newer teams as they cannot afford an actual LSD or lack the technical knowledge to use one. While the spool differential is most certainly the cheapest and the easiest option to implement, it isn't without it's huge drawbacks.

Some advantages first. The spool differential uses 100% of the torque that the engine can provide. There's no intermediate gearing between the engine sprocket and the differential sprocket, meaning that there's little to no drivetrain power losses (although that's hardly the main reason why one should choose a spool.) Because there's no speed differential, the tires don't care about about slippage. Track conditions don't affect straight-line acceleration unless those conditions affect both tires. The spool gives a very reliable straight-line acceleration, which is popular among drag cars.

Aside from an obvious lack of speed differential in the tires, this type of powertrain provides the most negative consequences in driving, most notable being the abhorrent excess of understeer. This understeer is usually observed as the car tending to go straight, even after the steering wheel has been turned all the way to the right or left. This happens because the traction of the front tires breaks before the traction of the rear tires break (the reverse, rear traction breaking before front traction, causes oversteer.) Aside from causing even more tire wear, the driver then cannot take a proper racing line, meaning that the car will not perform well in the timed events. Something like this also effects driver confidence, which is more important than one might see at first glance.

If a team is to take the dive and use a spool differential, it's important that the suspension and track widths of the car be taken advantage of. In order for a spool differential to perform well, the inside tire (the tire that would spin less) during a turn must be able to pick up off the ground so tire wear can somewhat be avoided. This is accomplished by incorporating as much body roll into the design of the car. Softer springs/suspension and a narrower front track is usually a good starting place as both of these can help force the body to roll, thereby picking up the inside tire. While every team absolutely should test their car before they take it to competition, the team running a spool must take special care to take weight off of the inside tire, while also balancing the driver's comfort and confidence in the turns.

The second differential to cover is one of a very mechanical nature, which should attract even the most casual engineering student. The automatic, torque-sensing LSD, or a torsens differential.

The torsen LSD relies on the principle that in a typical worm/worm gear linkage, the worm is allowed to move the worm gear, but the worm gear cannot drive the worm because of a significant gear reduction, i.e. lack of mechanical advantage the worm gear has over the worm. This principle allows the differential to lock immediately if it "senses" torque loss in one wheel, allowing the power loss from that wheel to distribute to the other wheel with more traction.

An obvious advantage of this differential system is that it offers the speed differential that the spool was lacking. As previously mentioned, this allows both tires to turn at different speeds during a turn to make up for a difference in turning radius between the two tires, which does a better job at prolonging tire life. Another advantage is that it does provide a torque biasing ratio (TBR) so that the wheel with less traction gets less torque and the wheel with traction gets more torque. In a situation with some wheel slip, the torque that the spinning wheel has is multiplied by the TBR and sent back through the differential to the other tire. Since this torque-biasing/differential locking is instantaneous, there is little to no tire slip and normal acceleration can occur.

A perhaps unexpected disadvantage of a torsen LSD is that the torsen can act as a regular open differential when the inside wheel is lifted during a turn. Recall from earlier that the spool differential benefits from actively making the car's rear inside tire lose traction or even ground contact on corner entry and exit. In a similar situation, the torsen differential would suffer from a complete loss of traction. Also recall that the torque that the tire with less traction has is multiplied by the TBR and provided to the other wheel. If a tire has a complete loss of friction, it's unable to apply any torque to the ground. This means the torque cannot be multiplied by the TBR since 0 lb*ft x TBR = 0 lb*ft. The car would suffer from a significant loss of acceleration until the tire fell back to the ground, which would ruin lap times if the event repeated enough times.

Other disadvantages torsen differentials have is that they are quite noisy as they are always engaged and they might exhibit some audible evidence of machining imperfections, although this shouldn't be a deal-breaker in negotiations with the electronics division of your team (sarcasm intended.)

When using a torsen differential, care should be taken when designing and driving the vehicle to avoid tire pickup. The suspension should be made to be stiffer so that there's minimal body roll and the track width/length should be longer to increase that body roll moment. Increasing the front track width might also be an option.

The third type of differential used is the Salisbury LSD, more commonly known as the clutch-pack LSD.

The clutch-pack LSD is of a simpler and somewhat lighter design that the torsen differential and offers a speed differential that the spool doesn't. It relies on a very strong, jarring loss of traction that will cause a rod in the differential to move between two heavy clamps, pressing the two clamps apart that press the clutch pack against the differential carrier, locking the differential. This allows for mostly open differential behavior in the corners and turns, but it locks under significant acceleration or significant braking.

The pin displayed above holding the spider gears is responsible for taking a sudden impulse of acceleration and translating that into outwards pressure that locks the spider gears and the differential case together, locking the differential. The pin slides between the two pressure cups that have an included pressure angle. This pressure angle dictates how easy the differential will lock. Greater pressure angles of 60 degrees will allow easier differential locking where shallower angles of 30 degrees will decrease the frequency of locking. These angles are incorporated into the cups in the transmission that load the clutch packs and lock them. This means that most of the time, the team running a limited slip differential will have multiple choices to choose from. In fact, they might be able to make their own cups that offer the pressure angle they're looking for.

Disadvantages that are often associated with clutch-pack differentials is that they are very expensive to run and maintain. Clutch packs need to be replaced fairly often depending on how hard the driver is on them. While I lack the experience and the numbers to make a quantified statement, suffice it to say that this will be costly in the long run. While the other types of LSD don't have any apparent long-term costs, the clutch-pack definitely has it's maintenance costs.

Clutch pack differentials are also very test intensive, meaning they take a long time to test. Of course the driver may be able to say within 15 minutes that the LSD isn't working for them, but to take that LSD out and switch new cups with different pressure angles takes easily a couple of hours. Adding this up over multiple testing sessions, it can easily take up to month to fully test the differential. This is of course to squeeze the last 5-10% of efficiency out of the vehicle itself. Some teams have no issue with testing their LSD. Others prefer a set-it-and-forget-it approach.

I suspect we will make a choice within the next few months on what type of limited slip differential our team will be using.

Photo Credits:

Formula Student Germany

https://www.formulastudent.de/pr/news/details/article/pats-column-january-2/

https://www.formulastudent.de/pr/news/details/article/design-judging-stuff/

Mechanical Engineering Design Blog

http://cadgill.blogspot.com/2013/08/torsen-differential.html

Quaife Manufacturing

http://quaife.co.uk/quaife-products/quaife-limited-slip-differential/

learnengineering.org

cartechbooks.com

In short, a rear differential in your everyday vehicle serves to make sure your tires don't slip every time the vehicle needs to turn, thereby extending tire life by reducing tire wear. This is because there is a different distance each wheel has to travel within a turn. In order to make sure each wheel travels a different distance in the same amount of time, there must be a speed differential between the wheels so that the wheels don't slip or suffer premature wear over time.

A secondary (and particularly important) purpose for choosing a rear differential is the ability to limit the amount of slip each tire has under acceleration and to bias torque to the rear wheel that has the greater traction.

Track conditions are usually considered to be inconsistent at best, meaning that most teams assume there will be some type of adulterant on the driving surface that impacts the tire's ability to mechanically adhere to the road. Classically, this type of contaminant would be water. However, these contaminants could also be simply loose gravel due to old asphalt, or even spilled oil due to an unlucky team's engine gasket failing. These act negatively on a tire's traction by adding unconventional lubrication between the tire and the pavement, lessening or even eliminating any traction the tire had. In an open differential, this completely stops the vehicle from moving until tire traction is regained.

In order to minimize this problem, most teams resort to using a limited slip differential (LSD), which does it's job by... limiting the slip. In broader terms, the LSD serves to limit the amount of traction lost between the tire and the pavement by biasing torque towards the other wheel, making sure that power isn't wasted, and making sure the other tire has enough power to accelerate the car, despite the traction loss that one of the rear tires has. The aforementioned track conditions are always considered in order to both be able to justify the use of a rear differential, and to finally aid in the decision process of a rear differential.

First, the most common type of rear differential that newer teams use the most is... none at all.

Typical breakdown of a spool differential.

Setup of a spool differential.

A spool type of differential, better known as a solid axle with the addition of a sprocket, is often used by newer teams as they cannot afford an actual LSD or lack the technical knowledge to use one. While the spool differential is most certainly the cheapest and the easiest option to implement, it isn't without it's huge drawbacks.

Some advantages first. The spool differential uses 100% of the torque that the engine can provide. There's no intermediate gearing between the engine sprocket and the differential sprocket, meaning that there's little to no drivetrain power losses (although that's hardly the main reason why one should choose a spool.) Because there's no speed differential, the tires don't care about about slippage. Track conditions don't affect straight-line acceleration unless those conditions affect both tires. The spool gives a very reliable straight-line acceleration, which is popular among drag cars.

Aside from an obvious lack of speed differential in the tires, this type of powertrain provides the most negative consequences in driving, most notable being the abhorrent excess of understeer. This understeer is usually observed as the car tending to go straight, even after the steering wheel has been turned all the way to the right or left. This happens because the traction of the front tires breaks before the traction of the rear tires break (the reverse, rear traction breaking before front traction, causes oversteer.) Aside from causing even more tire wear, the driver then cannot take a proper racing line, meaning that the car will not perform well in the timed events. Something like this also effects driver confidence, which is more important than one might see at first glance.

If a team is to take the dive and use a spool differential, it's important that the suspension and track widths of the car be taken advantage of. In order for a spool differential to perform well, the inside tire (the tire that would spin less) during a turn must be able to pick up off the ground so tire wear can somewhat be avoided. This is accomplished by incorporating as much body roll into the design of the car. Softer springs/suspension and a narrower front track is usually a good starting place as both of these can help force the body to roll, thereby picking up the inside tire. While every team absolutely should test their car before they take it to competition, the team running a spool must take special care to take weight off of the inside tire, while also balancing the driver's comfort and confidence in the turns.

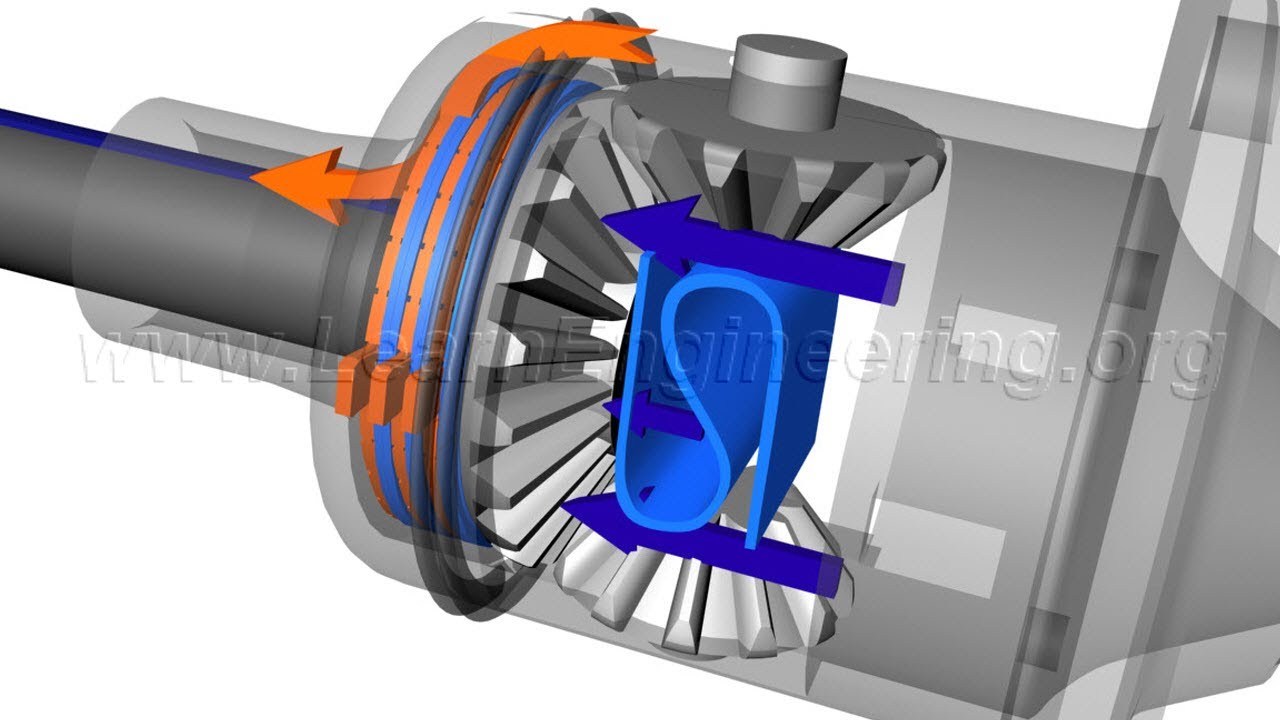

The second differential to cover is one of a very mechanical nature, which should attract even the most casual engineering student. The automatic, torque-sensing LSD, or a torsens differential.

Internals of a normal torsens system. The central axle can be considered to be a "worm", while the planetary-type gears can be considered to be the worm gear. Due to a large gear reduction, the axles can drive the planetary gears, but the planetary gears may not drive the axles.

Different style of torsen LSD. Quaife's Automatic Torque Biasing (ATB) differential features a helical design that allows for a more compact design, useful for swapping in LSDs into normal street cars, like the Honda Fit.

The torsen LSD relies on the principle that in a typical worm/worm gear linkage, the worm is allowed to move the worm gear, but the worm gear cannot drive the worm because of a significant gear reduction, i.e. lack of mechanical advantage the worm gear has over the worm. This principle allows the differential to lock immediately if it "senses" torque loss in one wheel, allowing the power loss from that wheel to distribute to the other wheel with more traction.

An obvious advantage of this differential system is that it offers the speed differential that the spool was lacking. As previously mentioned, this allows both tires to turn at different speeds during a turn to make up for a difference in turning radius between the two tires, which does a better job at prolonging tire life. Another advantage is that it does provide a torque biasing ratio (TBR) so that the wheel with less traction gets less torque and the wheel with traction gets more torque. In a situation with some wheel slip, the torque that the spinning wheel has is multiplied by the TBR and sent back through the differential to the other tire. Since this torque-biasing/differential locking is instantaneous, there is little to no tire slip and normal acceleration can occur.

A perhaps unexpected disadvantage of a torsen LSD is that the torsen can act as a regular open differential when the inside wheel is lifted during a turn. Recall from earlier that the spool differential benefits from actively making the car's rear inside tire lose traction or even ground contact on corner entry and exit. In a similar situation, the torsen differential would suffer from a complete loss of traction. Also recall that the torque that the tire with less traction has is multiplied by the TBR and provided to the other wheel. If a tire has a complete loss of friction, it's unable to apply any torque to the ground. This means the torque cannot be multiplied by the TBR since 0 lb*ft x TBR = 0 lb*ft. The car would suffer from a significant loss of acceleration until the tire fell back to the ground, which would ruin lap times if the event repeated enough times.

Other disadvantages torsen differentials have is that they are quite noisy as they are always engaged and they might exhibit some audible evidence of machining imperfections, although this shouldn't be a deal-breaker in negotiations with the electronics division of your team (sarcasm intended.)

When using a torsen differential, care should be taken when designing and driving the vehicle to avoid tire pickup. The suspension should be made to be stiffer so that there's minimal body roll and the track width/length should be longer to increase that body roll moment. Increasing the front track width might also be an option.

The third type of differential used is the Salisbury LSD, more commonly known as the clutch-pack LSD.

Internals of a clutch pack type of differential.

The clutch-pack LSD is of a simpler and somewhat lighter design that the torsen differential and offers a speed differential that the spool doesn't. It relies on a very strong, jarring loss of traction that will cause a rod in the differential to move between two heavy clamps, pressing the two clamps apart that press the clutch pack against the differential carrier, locking the differential. This allows for mostly open differential behavior in the corners and turns, but it locks under significant acceleration or significant braking.

Internals of a clutch pack limited slip.

The pin displayed above holding the spider gears is responsible for taking a sudden impulse of acceleration and translating that into outwards pressure that locks the spider gears and the differential case together, locking the differential. The pin slides between the two pressure cups that have an included pressure angle. This pressure angle dictates how easy the differential will lock. Greater pressure angles of 60 degrees will allow easier differential locking where shallower angles of 30 degrees will decrease the frequency of locking. These angles are incorporated into the cups in the transmission that load the clutch packs and lock them. This means that most of the time, the team running a limited slip differential will have multiple choices to choose from. In fact, they might be able to make their own cups that offer the pressure angle they're looking for.

Disadvantages that are often associated with clutch-pack differentials is that they are very expensive to run and maintain. Clutch packs need to be replaced fairly often depending on how hard the driver is on them. While I lack the experience and the numbers to make a quantified statement, suffice it to say that this will be costly in the long run. While the other types of LSD don't have any apparent long-term costs, the clutch-pack definitely has it's maintenance costs.

Clutch pack differentials are also very test intensive, meaning they take a long time to test. Of course the driver may be able to say within 15 minutes that the LSD isn't working for them, but to take that LSD out and switch new cups with different pressure angles takes easily a couple of hours. Adding this up over multiple testing sessions, it can easily take up to month to fully test the differential. This is of course to squeeze the last 5-10% of efficiency out of the vehicle itself. Some teams have no issue with testing their LSD. Others prefer a set-it-and-forget-it approach.

I suspect we will make a choice within the next few months on what type of limited slip differential our team will be using.

Photo Credits:

Formula Student Germany

https://www.formulastudent.de/pr/news/details/article/pats-column-january-2/

https://www.formulastudent.de/pr/news/details/article/design-judging-stuff/

Mechanical Engineering Design Blog

http://cadgill.blogspot.com/2013/08/torsen-differential.html

Quaife Manufacturing

http://quaife.co.uk/quaife-products/quaife-limited-slip-differential/

learnengineering.org

cartechbooks.com

Your car’s differential is a vital Cadillac Service Dubai component in its drivetrain and helps to provide power and traction to the wheels. Differentials are usually near the back of the vehicle and typically have either two or four-wheel drive.

ReplyDelete